This week, Langley-based forest company San Group was rewarded when the province unveiled plans to make the value-added sector a priority by improving access to timber.

On Thursday, the company reciprocated by promising to sink another $15 million into Port Alberni as it partners with the Port Alberni Port Authority to improve and take control of one of its deep-water berths.

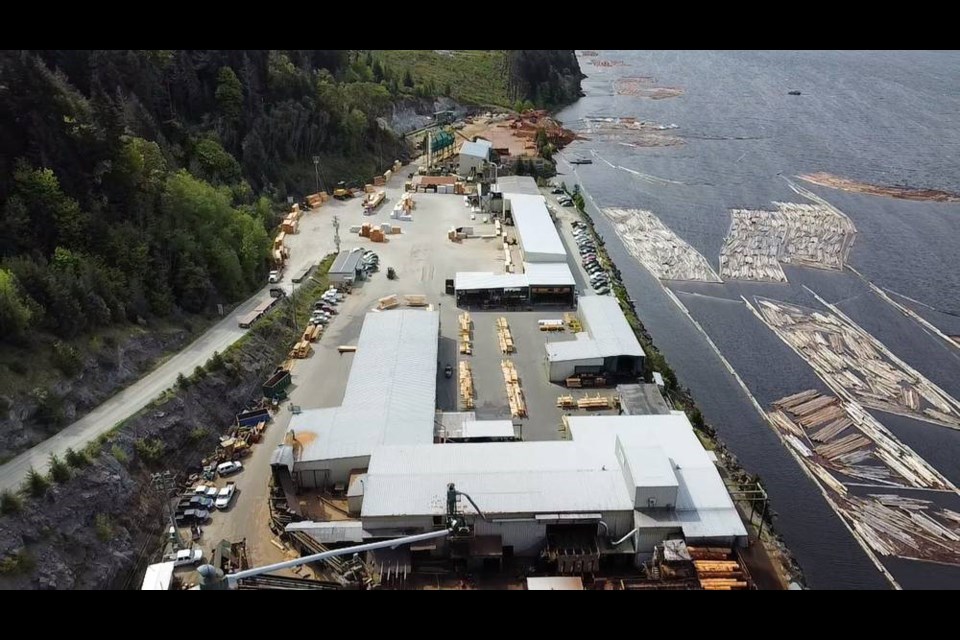

The deal will see San Group, which has already established three lumber manufacturing facilities in the region, operate shipping activities at the authority’s Berth 3, where it will invest in new facilities and equipment like storage silos and dockside cranes.

Kamal Sanghera, chief executive of San Group, said the port facility is “a major piece of our model to grow our value-added forest products business.”

He said the added investment will benefit all its operations and mean a more efficient operation for anyone using the berth to ship goods.

“We came to Port Alberni seeing the potential to grow our premier value-added forest products business and we have made great strides realizing that potential,” he said.

Port authority president Zoran Knezevic said the deal is good for the port and the region.

“The investments envisioned by San Group, as the province’s biggest value-added manufacturer, will help the community see a new, brighter future that leverages shipping from the Alberni Inlet to the world,” he said.

The San Group has invested more than $100 million over the last four years to establish three new facilities in Port Alberni that currently employ 425 people.

The investment includes a 300,000-square-foot value-added plant, made up of seven inter-connected buildings that produce more than 30 products.

Sanghera likes to say they can produce pretty much anything in a home that’s made from wood, from decking and mouldings to bannisters, shelving and everything in between.

“You name it,” he said. “And now you order from us and we can ship it from right here directly to the end user.”

The latest investment fits with the company philosophy of bringing all processes in-house and keeping fibre supply close to the mills.

“We are not moving the fibre out of the [Alberni Valley]; we are keeping it all here,” he said, noting that approach aligns with government plans to keep logs in B.C. and ensure the province gets true value from its resources. “What the government is saying, we are already doing.”

Sanghera said he had no idea the province was making its forest-modernization announcement earlier this week, but welcomed it, adding he hoped it will be as good as its word and that fibre supply will open up for secondary manufacturers.

With its new forest policy, the government plans to change the current forest tenure system to improve access to timber for smaller companies and value-added manufacturers, as well as increasing to 20 per cent the tenure held by First Nations from its current 10 per cent level.

The policy also intends to include a framework for compensation for companies like Western Forest Products, Canfor and West Fraser that lose harvesting rights under the new regulations.

Provincial Forests Minister Katrine Conroy said the modernization is designed to meet current challenges and the opportunities ahead.

“Modernization starts with setting intentions to change forest policy,” she said. “My ministry will continue to work with groups like San Group to ensure we deliver on the key changes as announced in the intentions paper.”

Conroy said she has been impressed with the San Group’s vision in investing in the valley and the impact it has had on revitalizing Port Alberni.

“San Group’s investments align with our government’s new vision for a forest sector that is more diverse, competitive, focused on sustainability and puts people and communities first,” she said in a statement.

Bill Collette, chief executive of the Alberni Valley Chamber of Commerce, said when the San Group first came to the valley, it was making promises that seemed impossible to fulfill.

“They’ve proved to all those who were skeptical that they were true to their word. In fact, they’ve not only met initial objectives, they’ve exceeded them,” he said. “Their latest announcement adds to the confirmation that they’re in for the long run and that they will continue to revamp the forestry industry with a focus on green technology, with the environment being a priority for them.”

Sanghera said one of the bonuses of processing and adding value to wood cut in the valley is reduced shipping and expulsion of carbon dioxide.

The company is also building a biomass plant to process waste wood generated from its operations.

San Group’s timing has been good, as its facilities have jumped to life while lumber and wood are fetching high prices. But Sanghera said his business works in any kind of market.

“What we have created here is not dependent on the market — we’re not dependent on two-by-fours and two-by-sixes. We have created our own products and created our own markets for them,” he said, noting the company currently exports to 40 countries.

“It does not matter if the market is good, bad or ugly, the value is always there because around the globe, anywhere, population is increasing – that means building homes.”